Howden to provide green hydrogen compressor

July 27, 2021

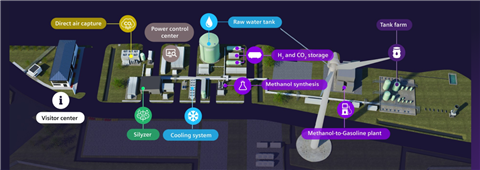

Siemens Energy’s Haru Oni project.

Siemens Energy’s Haru Oni project.

Johnson Matthey has hired Howden to build a hydrogen compressor for the world’s first methanol plant to harness energy from the wind in Patagonia, Chile.

The Haru Oni project will be used to supply environmentally friendly fuels to Europe and other regions. The project, under development by Siemens Energy in partnership with Johnson Matthey, Porsche and other corporations, will be the world’s first integrated and commercial large-scale plant to produce neutral e-methanol and e-gasoline, the company said.

The new production unit will deliver about 900,000 liters annually of e-methanol as early as 2022, with full-scale production units ready by 2026 that can produce 550 million liters of e-fuels annually.

The excellent wind conditions in southern Chile mean producing carbon-neutral fuel with wind power is a new and realistic opportunity, Howden said. The final products will be e-methanol and e-gasoline produced from methanol through the methanol-to-gasoline process and exported in the form of liquid fuel.

Johnson Matthey will license methanol technology and supply the engineering, catalyst and equipment for the project. The unit is designed to take atmospheric carbon dioxide as feedstock and convert it to e-methanol. The CO2 will be recovered by direct air capture and combined with green hydrogen, which is produced from water proton exchange membrane electrolysis.

“We are very excited to be collaborating again with Siemens Energy for this pioneering project to convert wind energy into clean, green, net-zero chemicals and fuels for a cleaner, healthier world,” said John Gordon, managing director of Johnson Matthey.

The plant will use wind-powered electrolyzers to split water into its components, oxygen and hydrogen. The plant will use Siemens Energy’s PEM (Proton Exchange Membrane) electrolysis.

After that, CO2 will be captured from the air and combined with the green hydrogen to produce synthetic methanol. In a third process step, approximately 40% of the methanol is then converted into synthetic gasoline.

To date, methanol is traditionally produced primarily from natural gas by means of steam methane reforming (SMR), a mature, highly integrated and cost-effective process. But, when derived from fossil sources, the production of this conventional “gray” methanol involves high CO2 emissions.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM