June 12, 2025

This continues a series of Cornerstones of Compression corollary articles that provide an historical look at the industries that drove the invention and technological evolution of compressors and that supported the growth and development of the industries that depended on them. This issue concludes a brief look at compressors developed for “making cold.”

Several companies introduced refrigeration compressors in the early 1880s. By 1891, the periodical, Industrial Refrigeration, contained advertisements from no less than 30 U.S. manufacturers of ice making and refrigeration machines to fill the burgeoning demand for ice making and mechanical refrigeration in breweries, meat packers, creameries, hotels, restaurants, steam ships and many more businesses.

By the late 1890s, demand increased for smaller size refrigeration compressors, having lighter parts and running at higher speeds, for moderate capacity refrigerating systems to serve hotels, restaurants, hospitals and various industrial plants. As steam power was not always available, other types of drive were introduced. Major producer Frick’s first direct-connected electric DC motor-driven compressor was built in the early 1900s. These adaptable machines paved the way for the wide acceptance of mechanical refrigeration.

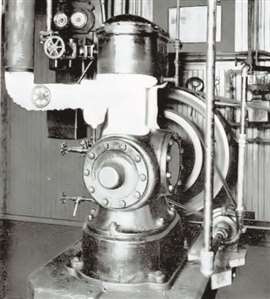

Frick long-stroke horizontal refrigeration compressors, c.1913.

Frick long-stroke horizontal refrigeration compressors, c.1913.

Frick, which had pioneered large vertical refrigeration compressors, also introduced long-stroke horizontal compressors in 1911, Fig. 1, which remained in use through the 1950s.

Enclosed Compressors Greatly Expand the Use of Refrigeration

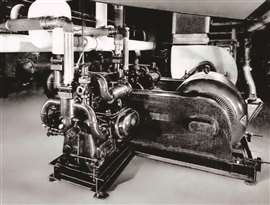

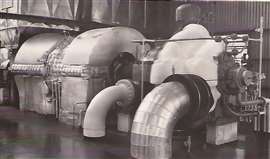

As the open-type compressor was made in smaller and smaller sizes, the A-frames which supported the cylinders were finally combined into one piece. From this arrangement, the enclosed compressor was later developed. First built in 1915, these machines, an example of which is shown in Fig. 2, were available in a range of sizes in time to serve the pressing demands of camps, food and powder plants, hospitals and ships in World War I. The enclosed design retained many of the desirable features of the slow-speed machines, but enclosed machines with automatic lubrication operated safely without constant attention. This opened the way for systems with automatic control in 1922. Lines of higher-speed electric motor-driven reciprocating compressors were developed, having as many as nine cylinders as shown in the Frick electric motor-driven air conditioning compressor in Fig. 3.

Frick electric-driven closed compressor.

Frick electric-driven closed compressor.

Centrifugal Compressors For Process Refrigeration

As process refrigeration requirements grew in size, especially in cryogenic, gas and chemical processing applications, centrifugal compressors quickly filled the need. The first use of centrifugal compressors in large industrial process refrigeration and chilling applications preceded World War II, and by the 1950s, several companies were producing large centrifugal machines for this sector. Fig. 4 shows a c.1960 centrifugal compressor in a propylene refrigeration application.

Electricity Leads to Practical Air Conditioning

Passive air conditioning dates back to prehistoric Egypt. Passive techniques remained widespread until the 20th century, when they began to be replaced by powered air conditioning developed around industrial refrigeration and ice making machinery. Physician Dr. John Gorrie used his compressor and ice making technology to make ice, which had been patented in 1850, to cool air for his patients in his hospital in Apalachicola, Florida. He hoped to eventually use his ice-making machine to regulate the temperature of buildings and envisioned centralized air conditioning that could cool entire cities. Unfortunately, the death of Gorrie’s main backer prevented the realization of his vision.

Frick electric motor-driven air conditioning compressor.

Frick electric motor-driven air conditioning compressor.

It was not until electricity became common that the development of lower cost and effective air conditioning units was possible. William H. Carrier built what is considered the first modern electrical air conditioning unit in 1901. It was able to control both the temperature and humidity of a large building. Air conditioning of large buildings and industrial facilities became increasingly common using electric motor-driven compressors such as the one shown in Fig. 3.

In 1914, the first domestic air conditioner was installed, in 1931 the first individual room air conditioner appeared, and air conditioning was being offered in automobiles by the late 1930s. The growth of air conditioning opened up an entire new market for small- and medium-sized compressors.

Rotary Screw Compressors Take the Place of Reciprocating Machines

In the 1950s, Svenska Rotor Maskiner AB (SRM) of Stockholm, Sweden had developed and licensed screw compressors that were very successful in displacing reciprocating machines in air compression applications. With further research, SRM developed higher pressure screw compressors that were optimized for refrigeration cycles. The first of these was delivered in 1962, and within five years, more than 1000 refrigeration screw compressors had been produced. By the late 1960s, screw compressors were beginning to displace most reciprocating compressors in refrigeration and air conditioning applications and they would soon dominate the industry.

Ingersoll-Rand centrifugal compressor in a propylene refrigeration application, c.1960.

Ingersoll-Rand centrifugal compressor in a propylene refrigeration application, c.1960.

Scroll Compressors Developed for Residential and Automotive Air Conditioning

The rapid growth of residential and automotive air conditioning in the 1970s led to strong demand for lower cost compact and efficient compressors that could be produced competitively in high volumes. This demand was met when in the early 1980s, the first practical scroll compressors were applied for automotive and room air conditioning in Japan. In 1987, after a 10-year development effort, Sidney, Ohio based Copeland Corporation, later part of Emerson, introduced its first scroll compressor. Its success led to introduction of a family of scroll compressors for applications ranging from residential and light commercial air conditioning to refrigeration for the food, healthcare and marine container industries. By the early 2000s, scroll compressors were prevalent in commercial and residential air conditioning and refrigeration applications.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM