Turbomachinery design, manufacturing technologies key to high-efficiency machinery

October 30, 2020

Advanced machinery beneficial for thermal, mechanical energy storage schemes

Authors’ Corner: Vishal Jariwala is an aerodynamics engineer with Elliott Group. Klaus Brun is the director of Research and Development with Elliott Group.

Introduction

Variable demand on electrical grids results in lower cost or surplus electrical power. Storing this power and holding it for a predetermined time and making it available on demand can significantly improve electric grid management. This is the fundamental premise of energy storage.

Additionally, renewable energy sources like wind, solar and ocean power are increasingly available to supplement conventional fuel-powered electricity generation. The intermittency of their output, however, makes it nearly impossible to integrate them into established electrical grids. Energy storage schemes can help mitigate this and achieve a lower carbon footprint in electric power generation. Innovative energy storage systems are a key building block for decarbonization and can enable balancing of the supply and demand of renewable energy, stabilizing the grids and reducing CO2 emissions in non-electricity sectors like heating and mobility.

Energy storage aims to affordably store and release energy derived by work and/or heat transfer processes from one instance in time to another. This implies that a typical power generation thermodynamic cycle can be split in terms of temporal sequences of work/heat transfer processes, thereby enabling energy storage. Three primary processes are common to all energy storage systems: a charging sequence, energy storage and a discharging sequence. Unlike energy conversion systems, these can be scaled independently to optimize the storage system for different applications.

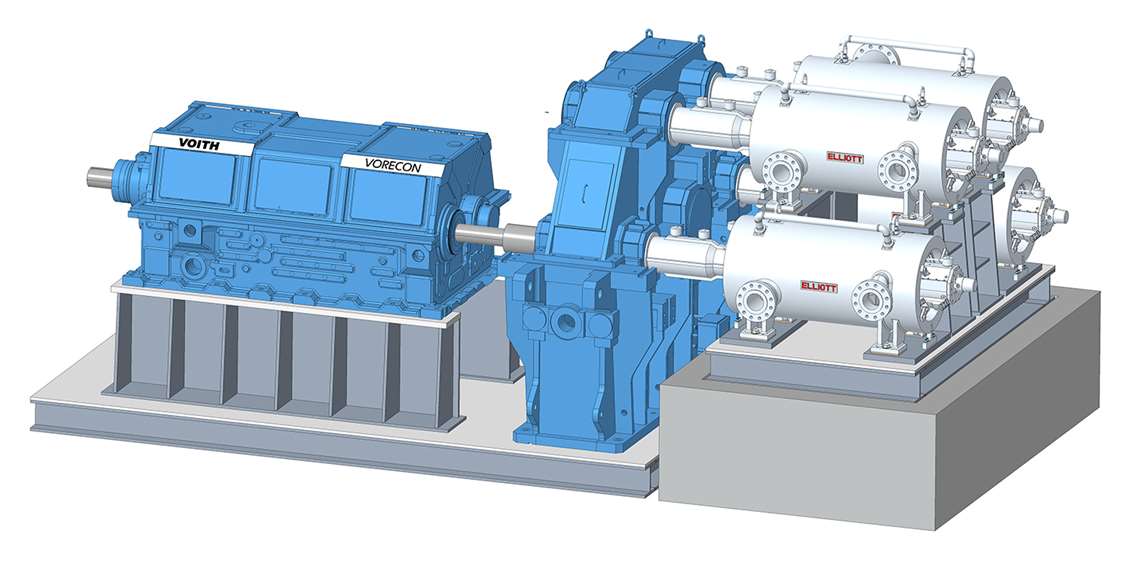

For many thermal and mechanical storage schemes, turbomachines are the main components in charging and discharging sequences. Although a mature technology base for turbomachinery design and development in power generation and process industry sectors exists, innovative energy storage schemes might require customization of this base rather than its direct adoption.

In this article, the need for high-performance turbomachinery is motivated by the requirements of advanced compressed air energy storage (CAES) technology. Integrated optimization of thermodynamic processes with the selection of appropriate turbomachinery architectures for affordable energy storage systems is emphasized. Advanced turbomachinery design and manufacturing technologies are recommended for achieving high-efficiency turbines and compressors without compromising life-cycle costs.

Read the rest of the article here.

This article was originally published in the Aug-Sept. 2020 issue of COMPRESSORTECH2. We only publish a fraction of our magazine content online, so for more great content, get every issue in your inbox/mailbox and access to our digital archives with a free subscription. Click here for a new subscription or here to renew your current subscription.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM