Read this article in Français Deutsch Italiano Português Español

Sundyne’s new compressor packages for hydrogen

August 07, 2023

Designed to meet growing demand in hydrogen mobility and industrial sectors

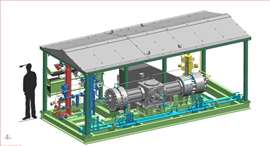

Sundyne has released four new standard PPI diaphragm compressor packages designed for the hydrogen mobility and industrial sectors. (Image: Sundyne)

Sundyne has released four new standard PPI diaphragm compressor packages designed for the hydrogen mobility and industrial sectors. (Image: Sundyne)

Sundyne announced four new standard PPI diaphragm compressor packages designed to make it easier, faster and more cost-effective to purchase, deploy and maintain PPI hydrogen compressors.

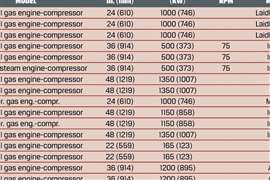

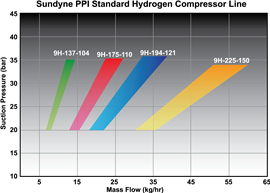

The new compressor packages cover a pressure range from 20 bar (290 psi) suction to 550 bar (8,000 psi) discharge, with flows from 10 kg/hr (22 lbs/hr) up to 60 kg/hr (132 lbs/hr). Each package can be supplied compliant with North American or European requirements. Available options include a modular closed-loop cooling water system as well as different enclosure designs for deployments requiring inclement weather protection.

“At Sundyne, we recognize the importance of lead-time to a project’s economics, especially in today’s hydrogen market,” said Sundyne’s Vice President of Hydrogen, Michael O’Neil. “Our new designs eliminate much of the traditional project engineering cycle and I’m excited about the value it will bring to our clients. Our goal was simple – to make it faster, easier and less expensive for our customers to compress Hydrogen.”

The chemical and pharmaceutical industries have a long history of processing hydrogen to make products. In the transportation industry, fuel cells are making industrial vehicles & long-haul buses and trucks emission-free. Utilities are increasing the volume of hydrogen that is blended with natural gas to generate power, and industrial markets are using hydrogen as an alternative to fossil fuels. Sundyne said its new standard units carry all the benefits of PPI diaphragm compressors, and they are a preferred choice for hydrogen applications, due to the following characteristics:

- High Compression Ratio: PPI diaphragm compressors are designed to meet the pressures required by mobility applications and industrial de-carbonization projects. Multiple compressors in the product family ensure a custom fit for a wide range of applications.

- Product Purity: PPI compressors feature triple diaphragm sets which ensure that the process gas is isolated from the hydraulic oil. This provides absolute process purity, which is critical for fuel cell applications – as even the slightest contamination can damage the fuel cell.

- Reliability: All process gas-contacting parts in a PPI compressor are made from corrosion-resistant alloys, making them ideal for hydrogen processing, as well as other applications involving hazardous and toxic gases.

- Environmental Safety: The static seals in PPI compressors ensure zero leakage of process gas to the atmosphere, and PPI’s Leak Detection System immediately detects diaphragm or seal issues.

- Lower Energy Costs: High-Efficiency compression, self-cooled packages combined with PPI’s rugged crankcases and drive trains are specially designed to deliver maximum compression at the lowest energy cost.

- Industry Standards compliance: All PPI compressors meet the API 618 standard.

- Explosion-Proof Certification: The package meets the various standards that address requirements for explosion-proof environments around the globe.

- Optional Custom Engineering: Sundyne can collaborate with customers to manufacture customized PPI systems that are optimized for the gas pressure, molecular weight, heat, corrosion and velocity of each customer’s application. Sundyne utilizes the latest technology in solids modeling and FEA analysis to ensure that all working components are designed & tested to minimize wear, improve sealing and reduce corrosive & erosive effects.

- Global Support: Sundyne’s global network of channel partners provides prompt & complete support (and spare parts) anywhere around the globe.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM