Sundyne Improves Centrifugal Compressors For Fuel Gas Boosting

November 20, 2020

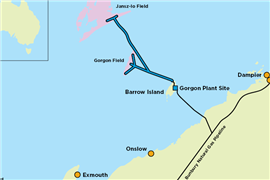

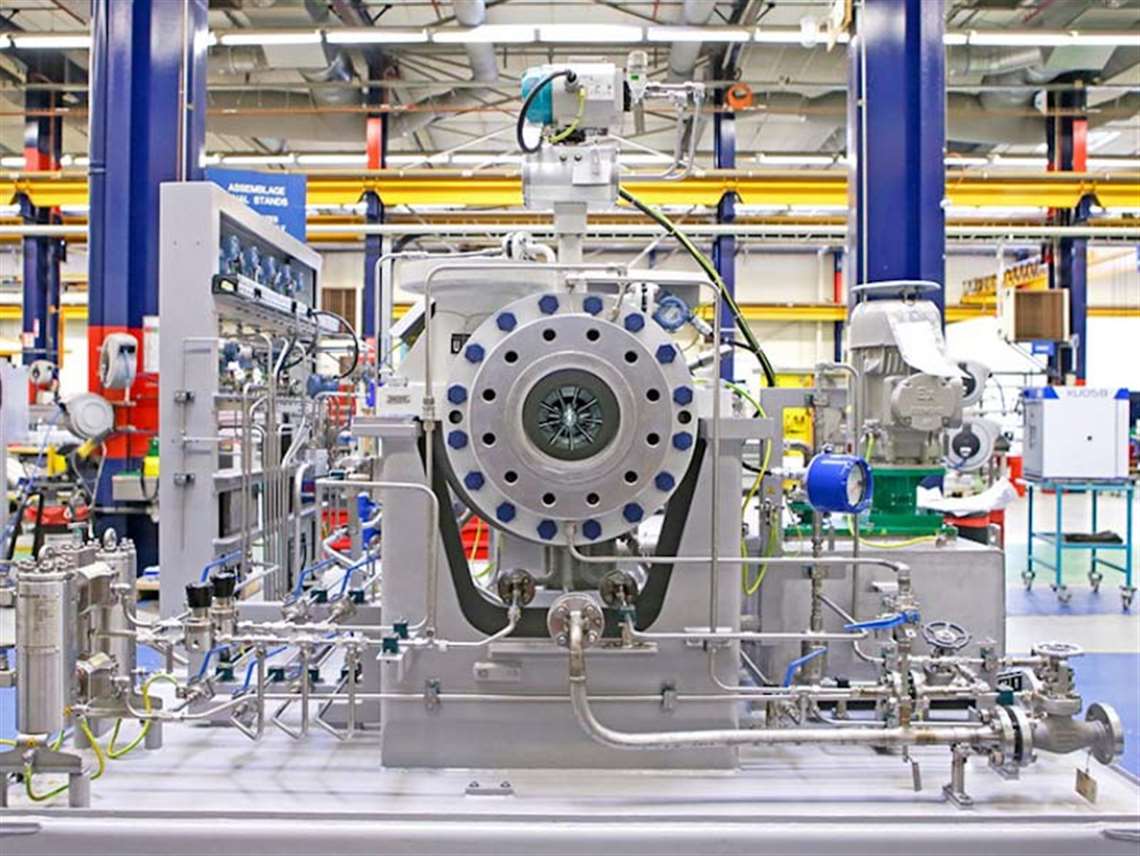

Sundyne has made enhancements to its “fit-for-purpose” centrifugal compressors used as fuel gas boosters for turbines generating electricity at refineries, chemical plants and other industrial facilities.

Co-gen power plants require gas pressures in the range of 250 to 750 psig (17.2 to 51.7 bar) to operate turbines optimally. Interstate gas pipelines transport gas at different pressures, ranging from 30 to 125 psig (2 to 8.6). With Sundyne’s centrifugal compressors, these plants can boost incoming gas pressures to levels required by turbines, the company said.

Enhancements to these Sundyne compressors include a high-speed digital control system, which integrates all the compressor control functionality into a single system (surge protection, load-sharing capabilities, compressor switching and discharge pressure control). Other features include the compressor’s dry gas seal configuration, oil-free design and a 75% smaller footprint than volumetric compressor technology.

Sundyne fully-integrated compressor trains include auxiliary systems such as air/water-cooled gas heat exchangers, nitrogen generators, valve skids and all the associated monitors and controllers.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM