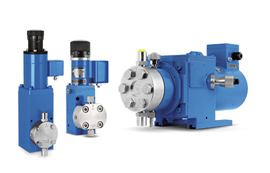

LEWA, a long-time specialist in diaphragm pump technology, has expanded its line of micro-metering pumps with two new model sizes designed to improve precision and cost efficiency in gas odorization systems. The new MAH4 and MBH6 models provide a broader range of flow and pressure combinations, addressing increasing market demand for smaller, more flexible odorization units.

Odorization—adding a strong-smelling chemical to otherwise odorless gases—is a critical safety process in gas distribution networks and industrial facilities. Micro-metering pumps are used to inject minute quantities of odorant into natural gas, LPG, CNG, LNG and biogas streams as they enter pipelines, tank trucks, railcars or storage vessels. Similar systems are also used to odorize oxygen, hydrogen and other industrial gases to ensure that leaks can be detected quickly, protecting personnel and property.

“Efficient odorization involves very precise dosing with small quantities of chemicals, so matching the pump to the application’s flow rate and discharge pressure is essential,” said Walter Richter, head of sales odorization and gas distribution at LEWA. “Operators often found that a pump suitable for the flow rate couldn’t deliver enough pressure, and vice versa. This can lead to oversizing, higher odorization costs and reduced accuracy. By introducing the MAH4 and MBH6 with new piston sizes, we now offer a wider selection of flow and pressure combinations for more effective, accurate and economical odorization.”

LEWA’s micro-metering portfolio includes the MAH, MBH, MLM15 and MLM40 series, covering flow rates from 10 ml/h to 55 l/h (0.0026 to 14.5 gph) and pressures up to 560 barg (8122 psig). The new MAH4 model operates at 16 barg (232 psig), complementing the 20–25 barg MAH3 and meeting PN16 pressure class requirements common in international gas networks. The MBH6 is a compact, higher-pressure model capable of 0.6 l/h at 42 barg (0.16 gph at 609 psig), designed for applications needing a smaller yet powerful metering solution.

Both pumps feature LEWA’s metal-diaphragm design and solenoid drive suitable for hazardous environments. The units are leak-proof and odorant diffusion-tight, preventing contamination and false leak alarms. A wide control range of up to 1:1000 enables precise metering across varying operating conditions, while high energy efficiency, low maintenance requirements and long service life reduce total cost of ownership.

“Optimal performance and low operating costs result from a fully engineered, proven solution,” Richter said. “The new additions to our micro-metering range are not simple scaled versions of existing models—they were extensively tested in the field under cold and high-pressure conditions to ensure reliability and safety throughout their service life.”

LEWA micro-metering pumps meet DVGW G280 standards and carry explosion protection certification up to EX-Zone 1.