Monkey Island LNG selects ConocoPhillips liquefaction technology for Louisiana export project

September 05, 2025

Optimized Cascade process chosen for planned 26 MTPA facility

Monkey Island LNG has selected ConocoPhillips’ Optimized Cascade liquefaction technology for its proposed 26 million tonnes per annum (MTPA) natural gas liquefaction and export facility in Cameron Parish, Louisiana.

The decision follows what Monkey Island LNG described as an extensive review of available technologies. According to the company, ConocoPhillips’ process was chosen for its operational flexibility, quick restart capabilities, high efficiency, and track record of exceeding nameplate capacity.

“After an extensive technology selection study and analysis on multiple technologies, Monkey Island LNG selected the Optimized Cascade process based on its operational flexibility, quick restart capabilities, high efficiency, and proven performance above nameplate capacity,” said Greg Michaels, CEO of Monkey Island LNG. “The ConocoPhillips Optimized Cascade Process will enable Monkey Island LNG to provide customers with long-term, secure, and competitively priced LNG supply. The decision marks a major milestone in advancing Monkey Island LNG’s mission to deliver TrueCost LNG – a radically transparent, cost-efficient model that eliminates hidden fees and aligns incentives across the LNG value chain.”

Darren Meznarich, head of ConocoPhillips LNG Technology and Licensing, noted that the company’s newest mega-module version of the Optimized Cascade process is designed to reduce costs, minimize land requirements, and lower project risk. “ConocoPhillips is pleased to support Monkey Island LNG with our new, mega-module Optimized Cascade template,” Meznarich said.

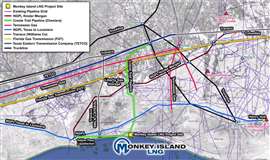

The 246-acre project site is located on Monkey Island in Cameron Parish, strategically positioned with access to deepwater shipping channels and abundant U.S. natural gas supply. With ConocoPhillips’ technology at the core of the design, Monkey Island LNG aims to position itself as a reliable and efficient source of LNG to international buyers.

ConocoPhillips’ Optimized Cascade technology, first deployed in the 1960s, has been used in more than 20 LNG trains worldwide. According to the company, the process uses a series of refrigeration cycles with different refrigerants to cool natural gas into liquid form, providing a combination of high efficiency and stable operations. The technology has been licensed for projects in the U.S., Qatar, Australia, Angola and Nigeria, among others.

The process is based on three multi-staged, cascaded refrigerant circuits using pure refrigerants, brazed aluminum heat exchangers and insulated cold box modules. ConocoPhillips has optimized the heat integration to closely approach the natural gas and refrigerant cooling curves, resulting in a highly efficient process. Pure refrigerants of propane, ethylene and methane are utilized, since their physical properties are ideal for heat integration. The refrigerant properties are also well known and predictable, contributing to unrivaled operating ease and flexibility.

Brazed aluminum heat exchangers and cold box modules allow for highly efficient heat transfer and can be designed to accommodate a wide range of LNG plant sizes. Depending on the natural gas feed stream composition, the design of your LNG train can include an integrated heavies removal unit (HRU) and/or a nitrogen rejection unit (NRU) to achieve your LNG plant performance and economic targets.

When client requirements call for high reliability and availability, the process can be configured in a proven “two-trains-in-one” arrangement, where one train of highly reliable heat exchangers and related process equipment is served by two parallel refrigeration turbine/compressor trains. Pioneered by ConocoPhillips, this approach was first used in the Optimized Cascade process, and has become widely accepted as a design that provides the highest plant availability, along with the widest range of turndown capability in the LNG industry.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM