INNIO, ExxonMobil release lubricant results

April 05, 2023

Jenbacher N Oil 40 extends oil drain intervals by up to two times, companies say

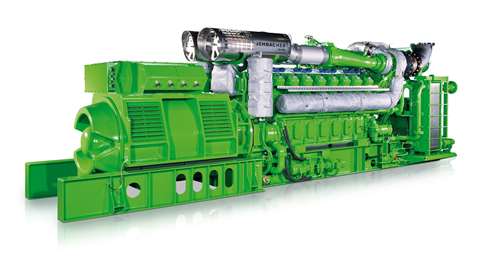

ExxonMobil and INNIO say Extensive field validation proves Jenbacher N Oil 40 enhances performance and reduces life-cycle costs. (Image: INNIO)

ExxonMobil and INNIO say Extensive field validation proves Jenbacher N Oil 40 enhances performance and reduces life-cycle costs. (Image: INNIO)

Following a collaboration agreement in 2020 between ExxonMobil and INNIO, the two companies produced Jenbacher N Oil 40– a high-performance, long-life lubricant formulated to meet the evolving needs of Jenbacher natural gas engines. INNIO’s latest operational data demonstrates the product’s advanced performance after over 8 million hours of operation in more than 800 units.

“Since its launch, Jenbacher N Oil 40 has been widely adopted across INNIO’s Jenbacher natural gas engine fleet. Extensive field validation proves that the lubricant can extend oil drain intervals by as much as two times. In an early adopter engine where the product has been in use for over 35,000 hours, the customer has achieved oil drain intervals of up to 7,000 hours in their Jenbacher J 612 F engine,” said Elisabetta Scossa, Europe commercial manager of energy at ExxonMobil. “Thanks to the product’s exceptional wear protection and detergent properties, it can help reduce life-cycle costs by up to 30%, supporting operators in the generation of reliable, efficient power.”

According to the companies, Jenbacher N Oil 40 can help engine operators:

- Extend oil drain intervals by up to two times

- Reduce waste oil disposal costs

- Increase engine reliability

- Promote productivity

- Avoid unscheduled maintenance

ExxonMobil and INNIO are using the insights obtained through data mining, maintenance reports, and oil analytics to develop new solutions to meet engine customers’ evolving needs and challenges.

“Our relationship with ExxonMobil continues to be highly productive,” said Dr. Andreas Kunz, chief technology officer at INNIO Group. “Jenbacher N Oil 40 proves how the combination of ExxonMobil’s lubrication expertise and our technology know-how can help power plant operators enhance operational reliability, productivity and sustainability ambitions – wherever they are in the energy transition.”

Jenbacher N Oil 40’s base oil and additive combination help stabilize Total Base Number (TBN) retention, the companies said. This technology allows operators to rely on long oil drain intervals and extended oil condemning limits without compromising the protection of critical engine parts. These benefits mean Jenbacher N Oil 40 can help reduce total life-cycle costs by up to 30%.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM