Baker Hughes introduces advanced flame detection sensor for gas turbines

May 15, 2025

New Flame Tracker ILG enhances reliability, supports hydrogen blends in midstream operations

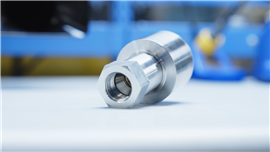

Baker Hughes said its new advanced flame detection technology, Flame Tracker Increased Low Gain (ILG), is designed to enhance flame sensing capabilities on gas turbines. (Image: Baker Hughes)

Baker Hughes said its new advanced flame detection technology, Flame Tracker Increased Low Gain (ILG), is designed to enhance flame sensing capabilities on gas turbines. (Image: Baker Hughes)

Baker Hughes has launched a next-generation flame detection sensor designed to improve flame monitoring accuracy and response time in gas turbine systems—a critical advancement as the midstream sector increasingly integrates hydrogen blends into fuel streams.

The new product, Flame Tracker Increased Low Gain (ILG), is part of the company’s Reuter-Stokes instrumentation portfolio. It was unveiled May 15 and is manufactured at Baker Hughes’ longtime Reuter-Stokes facility in Twinsburg, Ohio. The Flame Tracker ILG is designed for high sensitivity in low-light conditions, offering a significant reliability upgrade over its predecessor, particularly in demanding operational environments.

Flame sensors are essential components in gas turbines, serving as the primary safety mechanism to confirm flame presence during combustion. They play a critical role in preventing equipment damage and safety hazards by detecting flame instability or loss and triggering rapid shutdown protocols. However, the performance of these sensors can degrade when light levels are diminished due to condensation, lens fouling, or challenging sight line conditions.

According to Baker Hughes, the Flame Tracker ILG addresses these challenges through enhanced electronics that improve light sensitivity. The system can detect flame presence in less than 0.025 seconds and maintain performance even in applications where the flame view may be partially obstructed.

“Fuel flexibility and combustion stability are top of mind for our customers, especially as they evaluate hydrogen blends in their operations,” said a company spokesperson. “This technology builds on more than two decades of flame sensor innovation, giving operators a reliable, field-ready solution that’s compatible with new fuel strategies.”

Hydrogen-enriched natural gas blends are gaining traction as a pathway to reduce greenhouse gas emissions from midstream and power generation infrastructure. But using these blends introduces complexities in combustion monitoring due to hydrogen’s distinct flame characteristics. By extending flame detection capability to lower thresholds, the Flame Tracker ILG is intended to mitigate risk while enabling decarbonization efforts.

The launch reinforces Baker Hughes’ commitment to supporting energy transition technologies without compromising safety or operational efficiency. The company said the Flame Tracker ILG is available for both new installations and retrofit applications across a range of turbine platforms.

The product is the latest in a series of innovations emerging from Baker Hughes’ Reuter-Stokes brand, which has been supplying sensing and measurement technology to the energy industry for over 25 years.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM