Read this article in Français Deutsch Italiano Português Español

MAN compressors for Norway’s first unmanned platform

August 30, 2023

Total order of seven systems for two platforms

MAN Energy Systems received an order from Aker Solutions and Aibel comprises seven compressor units for three offshore oil and gas production platforms operated by Aker BP - Two HOFIM motor-compressor systems to be deployed for an unmanned gas production platform. (Image: MAN Energy Systems)

MAN Energy Systems received an order from Aker Solutions and Aibel comprises seven compressor units for three offshore oil and gas production platforms operated by Aker BP - Two HOFIM motor-compressor systems to be deployed for an unmanned gas production platform. (Image: MAN Energy Systems)

MAN Energy Solutions will supply compressor technology for the first unmanned Norwegian gas production platform.

MAN will deliver seven compressor systems to the Aker BP-operated production platforms, Hugin A and Munin, in the Yggdrasil area, and a new production and wellhead platform (PWP) in the Valhall field center.

The Valhall field is located around 290 km off the southern Norway coast, close to the maritime boundary with Denmark, and has produced over a billion barrels of oil equivalents since starting operation in 1982. The MAN compressor system there will be deployed by Valhall PWP-Fenris, the new platform development project, which will extend the field’s lifespan and more than double its gas-processing capacity, the company said. Yggdrasil, situated northwest of Stavanger, is the next major field development on the Norwegian shelf with gross resources of more than 700 million barrels of oil equivalent. The Yggdrasil area will be remotely operated from an integrated operations center and control room onshore in Stavanger. The Munin production platform, which is part of the development, will be designed from the start for crewless operation with neither helicopter deck nor living quarters. Munin’s topside will be provided by Aibel, while MAN’s scope of work encompasses the delivery of two compressor units as well as a comprehensive digital solution designed to fulfil the requirements for remote operation. The Yggdrasil area is expected to begin production in 2027.

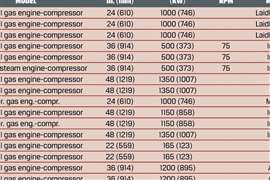

MAN Energy Solutions’ scope of delivery for the three projects comprises the supply of five HOFIM compressor units and two RB compressor skids:

- Munin: two HOFIM compression units as low-pressure and high-pressure compressors for gas export;

- Hugin A: two HOFIM compression units for gas export as well as two radial barrel compressor skids as gas lift (size RB 28) and first- and second-stage re-compressors (size RB 35);

- Valhall: one tandem HOFIM® compression unit for gas export.

Each HOFIM compressor unit will feature frame-size RB 45 compressors – with an integrated MAN high-speed motor, size M43. The HOFIM unit for Hugin A features an overhung compression stage on the opposite side of the motor to increase the overall pressure-ratio capability. The units will be developed, manufactured and tested at MAN’s premises in Zurich, Switzerland.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM