FCI meter designed for gas flow measurement

September 22, 2021

The FS10i flow meter series is an economical and easy to install solution to measure the flow rate of air and natural gas.

The FS10i flow meter series is an economical and easy to install solution to measure the flow rate of air and natural gas.

Fluid Components International recently unveiled its FS10i series of flow meters, which are designed for gas compression, boilers, clean room air flow, calciners, engines and furnaces. The FS10i series are the only SIL-2 rated thermal flow meters in its class, the company said.

The FS10i flow meter series is an economical and easy to install solution to measure the flow rate of air and natural gas. Its compact size, plug-in wiring and inline or insertion style threaded connection into the piping ensures quick and effective installation, FCI said.

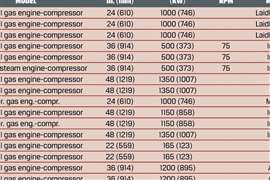

The versatile FS10i flow meters are designed for applications that include gas and air compressors efficiency and leak detection, blowers, boiler and burner air and gas fuel feed lines, calciners, clean room air exchange assurance, engines, furnaces, kilns, ovens, paint and sprayer booths, packaging equipment, and plant or campus sub-metering systems.

Providing direct mass flow measurement, the FS10i series flow meters require no additional pressure or temperature sensors or other components to infer flow measurement. Their sealed and no-moving parts sensor does not foul or clog, and requires no routine maintenance that ensures years of trouble-free, continuous operation. Independently evaluated SIL 2 certification as an HFT0 device makes them the optimum choice for safety instrumented system (SIS) critical processes, the company said.

Utilizing decades-long, applications-proven thermal dispersion flow sensing technology, the FS10i Flow Meters provide a fluid matched, calibrated and linearized 4-20mA output of flow rate, and a user programmable high or low flow alarm/trip point with a 1A SPDT relay output. For visual indication, the FS10i flow meters include a 10-segment LED array. This display illuminates proportionally to the flow rate and flashes if an alarm trip occurs.

The FS10i flow meters are available in both in-line and insertion style configurations to support installation in line sizes from 1 in. to 20 in. [DN25 to DN500]. They operate over a wide, 100:1 turndown from 1 to 400 SCFM (1,6 to 122 NCMH) depending on the fluid media and line size. Their 316L stainless steel wetted parts ensure superior corrosion resistance in the pipe. An aluminum housing, and protective, rubber boot surrounding the display area make the FS10i suitable for installation in demanding, IP 64/65/66 locations. The FS10i also carries global approvals: FM, FMc, ATEX, IECEx, and EAC/TR CU (Div 2) and Zone 2/Zone 22 installations.

The FS10i Series is suitable for use in a wide range of flow metering applications in manufacturing and process industries, and in their OEMs’, including electric power generation and more--wherever air, compressed air, or natural gas is being produced or consumed.

For line sizes of 1 or 2 in. (DN25 or DN50), the FS10i is built as an in-line solution with a stainless steel, female NPT pipe tee to ensure the instrument’s accuracy and repeatability in the installation.

For line sizes 2.5 in. (63,5 mm) or larger, users can select the insertion-style configuration in either a 6-or 12-in. (152 or 305 mm) length. The insertion-style configurations are outfitted with a 0.5-in. compression fitting, with either a Teflon or stainless steel ferrule to adjust the actual insertion depth to be compatible with a range of pipe diameters and achieve inserting the sensor element to the center-point of the pipe.

User set-up is performed using a PC connection to the instrument’s serial port, included computer interface dongle and using FCI’s free software utility program. User set-up functions include scaling of the 4-20mA output to the desired flow range and engineering units, setting the relay trip point and adding hysteresis or time delay to the relay’s action, etc, the company said.

The FS10i flow meters are manufactured in the USA at FCI’s Southern California operations. Each meter is precision calibrated on FCl’s air and gas flow stands, which are outfitted with NIST and ISO/IEC 17025 traceable equipment to ensure their accuracy and measurement repeatability, the company said.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM