Elliott offers new expander

June 13, 2022

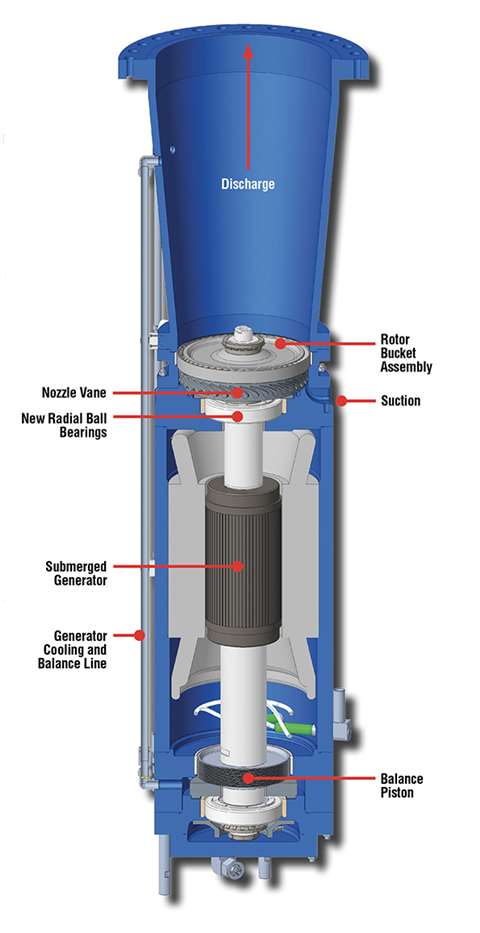

Elliott’s new cryogenic expanders do not require a Joule Thomson (JT) valve at the downstream and have generator nameplate ratings ranging from 300 kW to 2.2 MW.

Elliott’s new cryogenic expanders do not require a Joule Thomson (JT) valve at the downstream and have generator nameplate ratings ranging from 300 kW to 2.2 MW.

Elliott Group is offering an impulse-type, two-phase cryogenic expander that allows for the expansion of liquefied gases into two-phase mixtures.

Harnessing the energy of two-phase expansion increases the expander’s generator output, reduces boil-off losses and improves the overall liquefaction and cooling processes. Each expander is custom-designed and built for use in LNG liquefaction, refrigeration, and separation processes, as well as to improve overall efficiency, Elliott said.

Based on proven impulse turbine blade technology, this cryogenic expander has optimized staging to minimize axial load at the radial ball bearings. Because it tolerates a high content of vapor mass, it is offered for liquefaction and refrigeration processes with relatively high vaporization capability in cryogenic hydrocarbon applications.

The isentropic efficiency of these units is estimated to be at around 60-70%, depending on the mass flow rate and unit pressure drop. They do not require a Joule Thomson (JT) valve at the downstream and have generator nameplate ratings ranging from 300 kW to 2.2 MW for a single unit. If the process requires high-flow output, these units can be installed and operated in parallel configuration.

“Elliott’s impulse-type, two-phase cryogenic expander has optimized staging for high efficient operation with vapor mass content up to 35%,” said Enver Karakas, senior engineer at Elliott. “This cryogenic expander can increase your liquid production by around 7% compared to a JT expansion in natural gas or hydrogen liquefaction plants.”

The new cryogenic expander also features an axial flow impulse design with reduced overhung and stage reaction; a vertically suspended upward flow configuration; a single-shaft compact design with submerged generator; and cooling and balance lines to adjust pressure and flow to efficiently cool the submerged generator and lubricate the ball bearings.

The new expander can be retrofitted to existing LNG liquefaction and cooling applications. The impulse-type, two-phase cryogenic expander improves the efficiency of the liquefaction process with an estimated LNG production gain of 5-7% by reducing boil-off. This, coupled with its other benefits, offers the possibility of investment payback in a number of months, Elliott said.

Elliott Group designs, manufactures, and services technically advanced centrifugal and axial compressors, steam turbines, power recovery expanders, and cryogenic pumps. Elliott is a wholly owned subsidiary of Ebara Corporation, based in Tokyo, Japan.

Elliott’s expanders are tested at the company’s cryogenic performance test facility, which simulates actual site conditions. (Photo: Elliott Group.)

Elliott’s expanders are tested at the company’s cryogenic performance test facility, which simulates actual site conditions. (Photo: Elliott Group.)

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM