Burckhardt oil-free compressor reaches 10000 hours of continuous operation

October 20, 2021

The 5-stage fuel gas compressor system is designed to manage the vessel’s boil-off gas with a flow of up to 4700 kg/h.

The 5-stage fuel gas compressor system is designed to manage the vessel’s boil-off gas with a flow of up to 4700 kg/h.

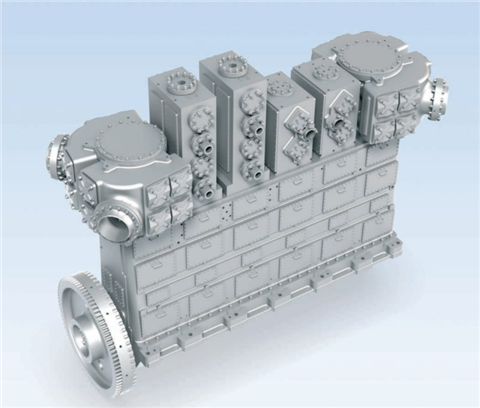

A type LP250 Laby-GI Compressor built by Burckhardt Compression recently completed 10000 hours of continuous operation on a 174,000 cbm LNG carrier, the company announced. The compressor is the world’s first oil-free reciprocating high-pressure fuel gas compressor in service.

This technology enables Burckhardt to compress gas to 300 bar in a large, ring-sealed compressor system without cylinder lubrication. This type of compressor is used on LNG carriers, where natural gas warms up during storage and transportation. The evaporated boil-off gas must be economically managed by using it as a fuel or re-liquefying it.

Both, dual-fuel engines and re-liquefaction plants, require a certain operation pressure, ranging up to 300 bar. To meet that need, Burckhardt Compression designed a compressor to handle gases at low temperature and high pressure while operating at sea.

The 5-stage fuel gas compressor system is designed to manage the vessel’s boil-off gas with a flow of up to 4700 kg/h. Dry-running sealing technology saves significant expenditures for cylinder lubrication and filter maintenance, the company said.

The performance of the high-pressure reliquefaction system is improved because of the absence of fouling caused by small traces of residual oil carried within the gas. The oil-free gas compression completely removes the need for oil separation and gas filtration technology and guarantees the cleanliness of the heat exchanger in the high-pressure reliquefaction system, Burckhardt said.

In addition, maintenance intervals for the oil-free high-pressure sealing technology are 8000 operating hours. The Laby-GI Compressor combines sophisticated cryogenic, low-pressure labyrinth piston design and state-of-the-art ring-sealed high-pressure technology on a single compressor frame, the company said.

This allows simultaneous fuel gas supply to low-pressure 4-stroke auxiliary engines and high-pressure gas supply to the 2-stroke main engines and a dedicated high-pressure re-liquefaction system. All Laby GI compressors are of gas-tight design, which prevents gas emissions into the atmosphere. The sealed design of the compressor helps to prevent significant greenhouse gas emissions by recycling all internal leakages without the need for any further purge gas utilization, the company said.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM