Baker Hughes to provide turbo-compression technology for Greek pipeline

March 31, 2022

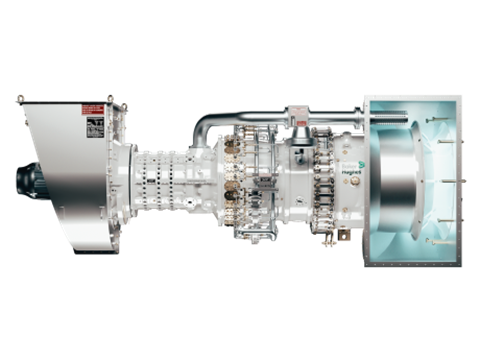

The entire NovaLT family of gas turbines is 100% designed and manufactured in Baker Hughes plants in Italy.

The entire NovaLT family of gas turbines is 100% designed and manufactured in Baker Hughes plants in Italy.

The construction arm of GEK TERNA Group has awarded Baker Hughes a contract to supply gas turbines and compressors that can run on a blend of natural gas and hydrogen for a new compression station in the Greek natural gas transmission system. The compression station will serve domestic gas supply in Greece.

Baker Hughes will provide three compression trains that include three NovaLT12 hydrogen-ready gas turbines and three PCL compressors. For this project, the technology has been designed to support the compression station with the capability to transport up to 10% hydrogen, Baker Hughes said.

The station is expected to enter operation in 2024 and directly supports the European Union’s goals to accelerate the development of clean hydrogen and ensure its role as a cornerstone of a climate-neutral energy system by 2050, Baker Hughes said.

In 2020, Baker Hughes collaborated with energy infrastructure network provider Snam to introduce the NovaLT12 gas turbine for transporting hydrogen-gas blends within its pipeline network in Italy, marking the first time a hybrid hydrogen turbine was integrated into a natural gas pipeline system.

“Technology is a critical enabler of the energy transition, and our wide range of climate technology solutions helps customers to decarbonize their operations. In addition, this project will advance the understanding of what’s capable in a hydrogen economy and supports Europe’s energy transition goals,” said Rod Christie, executive vice president of turbomachinery & process solutions at Baker Hughes. “Leveraging our strong foundation of technical expertise, Baker Hughes is proud to work with customers like TERNA to bring new energy frontiers forward in support of climate action, as well as helping to ensure critical natural gas and hydrogen supplies across Europe.”

Baker Hughes said its experience in the treatment of hydrogen began in 1962 with its first hydrogen compressor. Today, the company’s technologies serve the entire hydrogen value chain, from production to transportation and utilization. The company’s portfolio includes advanced compressors, gas turbines, valves, centrifugal pumps, non-metallic pipes, hydrogen sensors, monitoring and diagnostics including inspection solutions for hydrogen embrittlement in production and storage, as well as clean, integrated power solutions to produce power with hydrogen and hydrogen blends.

The design of the NovaLT12 allows for blends of between 5% and 100% hydrogen; the entire NovaLT family of gas turbines is 100% designed and manufactured in Baker Hughes plants in Italy.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM