Cummins upgrades engines for gas compression

May 07, 2021

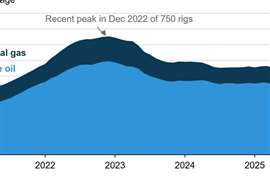

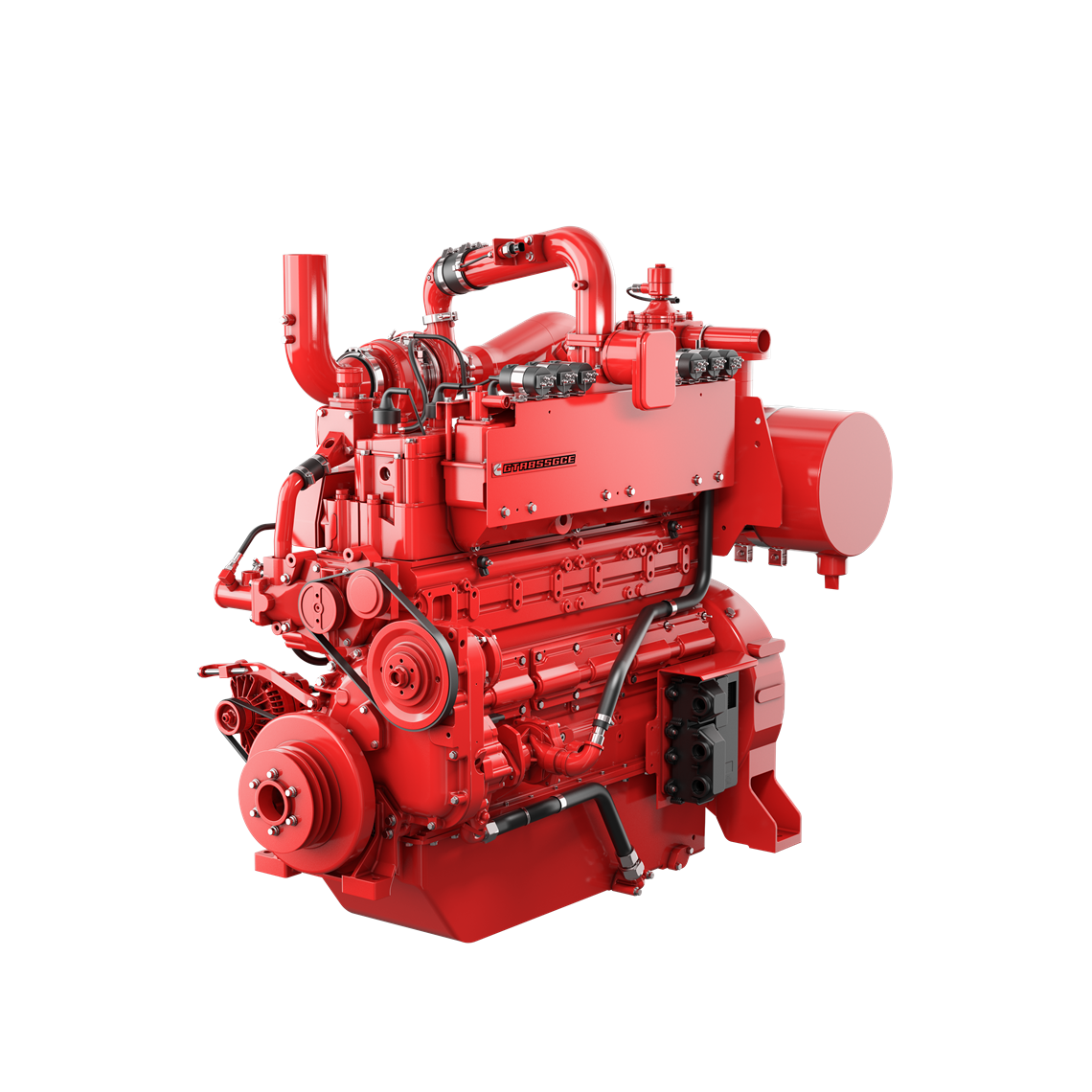

Cummins Inc. new GTA855GCE engine.

Cummins Inc. new GTA855GCE engine.

Cummins Inc. announced the availability of two gas compression engines that incorporate new Murphy control systems.

The GTA855GCE and G855GCE engines incorporate the Murphy Engine Integrated Control System (EICS), including a simplified set-up process and extensive diagnostics, Cummins said. Available with a horsepower range up to 286 hp (213 kW) at 1800 rpm, the GTA855GCE experiences a greater than 10% power range increase with the new integration. Both engines are backed by support to keep maintenance costs minimal and uptime maximized, the company said.

Cummins said the Murphy EICS, which combines ignition, air/fuel ratio controller and speed governing functions in a single-engine control module (ECM), helps improved power and performance of the engines. The EICS capacitive discharge ignition system incorporates smart-coil technology designed to provide ultra-reliable spark delivery, individual cylinder diagnostics and knock-sensing capabilities.

The engine integrates proven components and controls technology, making it capable of reliable upstream compression, Cummins said. It is designed to keep gas flowing with a minimum of maintenance costs.

“In an energy industry where uptime and reliability are invaluable, the GTA855GCE and G855GCE engines with EICS integrations give customers improved start-up and operational experiences, while also leaning on proven engine capability and a world-class service network,” said Patricio Escobar, Cummins segment director, oil & gas markets.

In addition to the EICS engine control system, the GTA855GCE and G855GCE are designed to optimize intake air and exhaust flow with optimized, high-temperature valves, valve seat inserts, and guides used in rich burn three-way catalyst applications. Both engines can handle a wide range of fuel compositions with minimal adjustments.

The lubrication system includes a high-capacity oil pan with combination full-flow and bypass oil filters for extended drain intervals and reduced maintenance costs. Cooling for this engine is provided by a two-pump, two-loop system with separate aftercooler and jacket water cooling circuits to lower intake manifold temperatures and increase output.

Coolant filters help eliminate any potential for corrosion. Air/fuel control is managed by a direct-acting regulator assembly while speed controls use electronic governors to stabilize the rpm. An optional input allows customers to monitor and control suction or discharge pressure.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM