Baker Hughes Gets Major LNG Order In Qatar

September 29, 2020

Baker Hughes announced an order with longtime partner Qatar Petroleum to supply multiple main refrigerant compressors (MRCs) for Qatar Petroleum’s North Field East (NFE) project, executed by Qatargas.

The total award is part of four LNG mega trains, representing 33 million tons per annum (MPTA) of additional capacity, which will increase Qatar’s total liquefied natural gas (LNG) production capacity from 77 to 110 MTPA and help propel the Gulf nation to global LNG production leadership by 2025. This order is among the largest LNG deals secured by Baker Hughes in the past five years, for both MTPA and equipment awarded.

With Qatargas already operating six existing LNG mega trains driven by Frame 9E gas turbine refrigerant compressors provided by Baker Hughes, the NFE project underscores the collaboration between Baker Hughes, Qatar Petroleum and Qatargas in one of the world’s most complex LNG projects.

“This milestone deal illustrates the continued strength of Baker Hughes’ partnership with Qatar Petroleum, which began 25 years ago upon our delivery of the first LNG train in Qatar,” said Lorenzo Simonelli, chairman and CEO of Baker Hughes. “As we look ahead to the next two decades, in almost any scenario natural gas will be a key transition fuel, and likely a destination fuel for a lower carbon future. Building on our track record of delivering proven, reliable and highly efficient LNG technology, we remain committed to taking energy forward in Qatar for more years to come.”

As part of the company’s overall commitment to reach net zero by 2050 and support customers in decarbonizing their operations, Baker Hughes said the NFE project will incorporate the latest advancements in compression technology, including enhancing machine performance and reducing 60,000 tons of CO2 per train each year without any reduction in LNG production.

In addition, the new compression trains will be designed and produced by leveraging the latest manufacturing technologies and processes, minimizing raw material and emission intensive processes involved – thus reducing CO2 emissions during manufacturing production up to 10%, the company said.

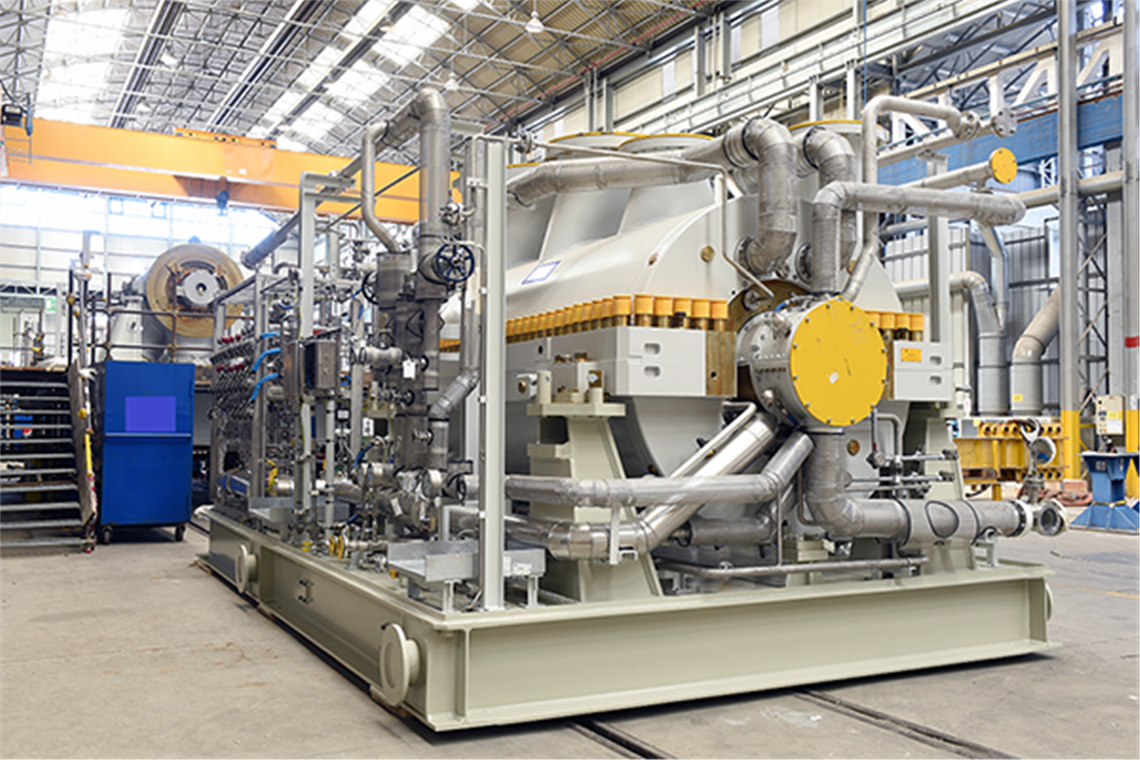

Each MRC train will consist of three Frame 9E DLN Ultra Low NOx gas turbines and six centrifugal compressors across four LNG mega trains for a total scope of supply of 12 gas turbines to drive 24 centrifugal compressors. Packaging, manufacturing and testing of the gas turbine/compressor trains will take place at Baker Hughes’ facilities in Florence and Massa, Italy.

The North Field is the world’s single largest non-associated natural gas field. The NFE project, owned by Qatar Petroleum and operated by Qatargas, is the first phase of the North Field LNG Expansion Project, announced in 2017. First gas from the Expansion Project is expected to be produced by the end of 2025. The second phase of the North Field LNG Expansion Project, called the North Field South project (NFS), will further increase Qatar’s LNG production capacity from 110 MTPA to 126 MTPA.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM