The Air In There

October 24, 2017

At first glance, it may not seem that green power fits in the oil and gas landscape.

Between 2000 and 2010, however, oil and gas companies based in the United States spent about US$9 billion in renewable technologies, according to the West Virginia Independent Oil & Gas Association. In May 2016, Shell established a renewables division known as New Energies, investing US$1.7 billion into it.

“The oil & gas industry is setting the lead in green energy,” said Steve Morgan, president and CEO of Clean Energy Generation (CEGEN). “Most companies out there have some form of green energy division. They are looking for new ways to make them more viable and much cleaner.”

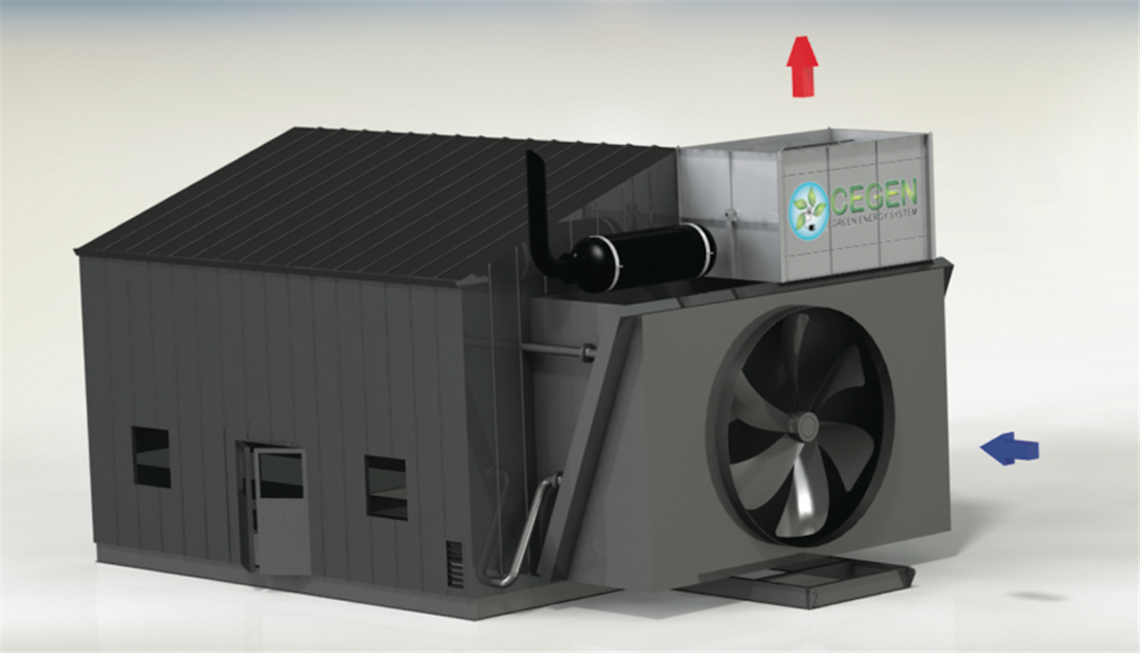

CEGEN is one of those companies. The startup has created the CEGEN green energy system, designed to covert the exhaust air from the fans on natural gas compressor coolers into power. That power can then be used for anything that requires electricity at a compressor station, such as lighting, ventilation, gas detection and onsite offices.

The CEGEN green energy system is an 18 x 7 x 8 ft. (5.5 x 2.1 x 2.4 m) box that houses three savonius turbines. The box sits on top of the exhaust portion of a cooling fan, which feeds a constant stream of exhaust air into the system. The system, which bolts onto the fan, does not affect the facility’s footprint or the fan’s performance, Morgan said. The unit weighs 4000 lbs. (1814 kg) and adds less than 0.1 in. water gauge (0.24 mbar) of static pressure to the fan.

The fan speed and the compressor’s output impact the power generated by the system. The exhaust wind of a typical 1500 hp (1119 kW) gas compressor allows the system to produce 7 kW or 61,320 kWh/annum. For lower wind speed applications, the system has 2.7 and 6.7 hp (2 and 5 kW) models available.

The power generated through the CEGEN green energy system is not limited to basic electrical needs. The system can also mitigate the need for external power sources. One such source, especially for remote facilities, is power lines, which can run an average of US$285,000 per mile, Morgan said. The system can also supplement the power needs of

a compressor station, forgoing the need for a generator. In some cases — larger facilities with multiple units — the system will allow companies to sell electricity back to the grid.

Given the nature of emissions regulations, installing a CEGEN green energy system instead of a gas-burning power generation unit can help cut back on CO2 and allow for an additional compressor at a facility to increase production, Morgan said.

“Most compressors today have a generator on them, which uses about 2 kW of power,” he said. “If you’re producing 7 kW (with the system), you could power three compressors.”

The use of power at compressor stations served as the driving force behind the idea for the CEGEN green energy system. Early last year, Morgan noticed how many facilities with large carbon footprints were either burning through their own natural gas supply for power or using thermal recovery to gain meager electrical returns (500 W).

“It dawned on me that no one tried to capture the wind off the cooler,” he said.

While at a social gathering, Morgan, with cocktail napkins as his canvas, began plotting out his idea with Darcy McIntosh, a master electrician with experience in wind technology. The pair moved into McIntosh’s garage and traded the napkins for whiteboards. By fall, they started testing scaled prototypes. Shortly thereafter, they had a scaled version of the system.

A yard test of the full-size model on a large gas compressor cooler took place in Calgary, Alberta, Canada on a site owned by Sage Energy Corp, a natural gas compression packager. After testing, Harvest Operations, a Canadian energy provider and subsidiary of Korea National Oil Corp. (KNOC), will obtain the unit to conduct long-term review and analysis.

During these testing phases, CEGEN did not sit idle. The company spent that time marketing the system not only in the United States, but also in the Middle East and Australia. While the midstream and upstream natural gas market is

the primary target, Morgan said the system is relevant for mining and other industrial applications, such as heating, ventilation and air conditioning (HVAC).

As CEGEN looks to the future, Morgan anticipates this product opening the door for more green energy opportunities within the oil and gas industry.

“My goal is to take CEGEN from a product to a brand that will represent innovative thinking to reduce natural gas usage at a facility,” he said. “I really see CEGEN as a vehicle to make things better for the energy industry as well as the fossil fuels and green energy movements.”

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM