Optimizing Nitric Acid Production

September 29, 2017

MAN Diesel & Turbo has introduced an optimized train concept for the fertilizer industry, the “Namax,” utilizing an AG-MAX1 axial compressor. The company said this concept raises production efficiency of nitric acid to a new level.

The Namax compressor train with MAX1 technology has been recently ordered by end customer Grupa Azoty in Poland for the licensor Thyssenkrupp Industrial Solutions. Grupa Azoty will use Namax to expand its fertilizer production in Pulawy, in eastern Poland.

“Nitric acid is one of the most important feedstocks in the industry worldwide,” said Dr. Lothar Wallscheid, vice president at MAN Diesel & Turbo in Oberhausen (Germany). “For the energy-intensive production process we have created a highly efficient train concept based on the MAX1 as air compressor. Among its many advantages, this means one thing in particular for the production of nitric acid: far greater efficiency with reduced investment.”

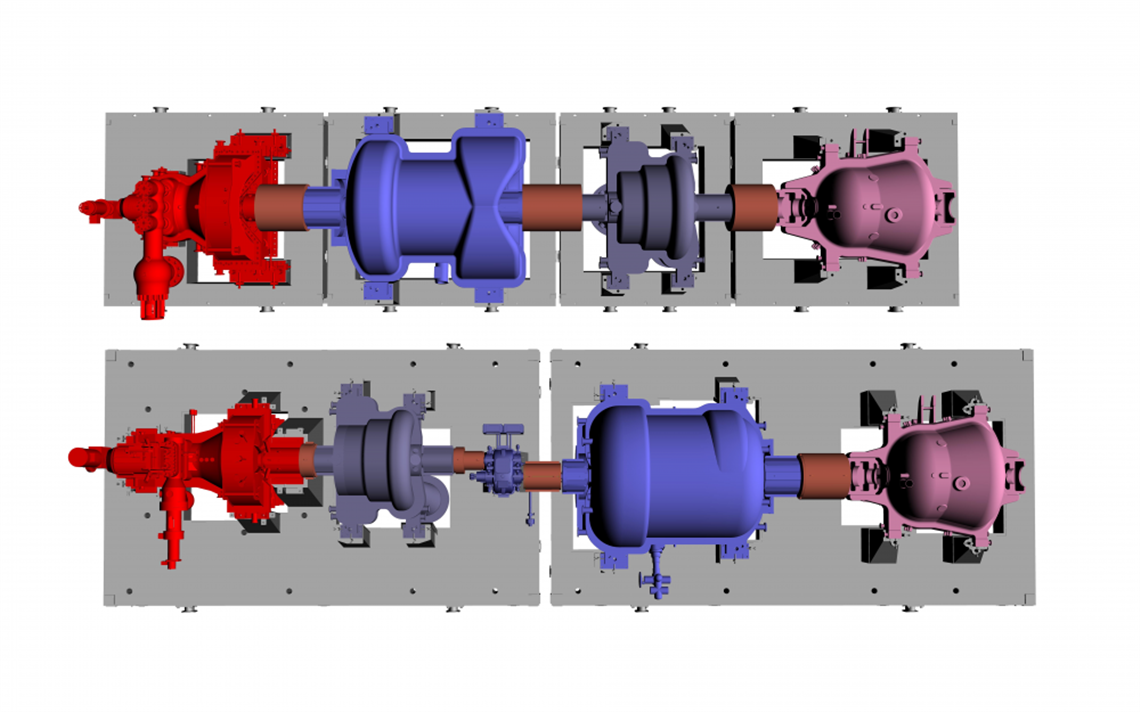

While previous concepts used an intermediate gearbox to couple the machines in the train, the great advantage of the Namax concept is its direct drive, meaning there is no longer need for a gearbox. MAN Diesel & Turbo said that, compared to the machine trains to date, this allows efficiency to be boosted by several percentage points, while at the same time reducing the energy input and the operating costs for nitric acid production.

The Namax concept features a MAX1 as air compressor, along with other proven MAN machinery: a centrifugal compressor for NOx compression, a steam turbine and an axial expander providing the drive power.

According to MAN Diesel & Turbo, the fact that all four machines come from a single source means that the complete train can be perfectly matched, allowing the demanding process of nitric acid production to be trimmed for maximum efficiency.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM