MAN Supplying Compressor Systems For Baltic Project

March 06, 2019

MAN Energy Solutions received an order from Estonian TSO Elering AS to deliver two MOPICO compressor systems for gas transport.

It marks the company’s first order within the Baltic Energy Market Interconnection Plan (BEMIP), a energy supply initiative for the Baltic region.

“We are very proud to have convinced our customer with MAN’s unique technology know-how,” says Uwe Lauber, CEO of MAN Energy Solutions. “With this order we further strengthen our position in the European gas transport market with our compressor solutions.”

As the next step in integrating the Baltic states Lithuania, Latvia and Estonia into the European energy grid, the Balticconnector pipeline is part of the BEMIP plan. This pipeline is designed to ensure the connection of the Finnish and Estonian gas grids. Starting in the Finnish town of Siuntio, it runs to Ingå (Finland), continuing underwater to Paldiski (Estonia) and stretches via Kiili to Puiatu. The project is co-financed by the Connecting Europe Facility of the European Union.

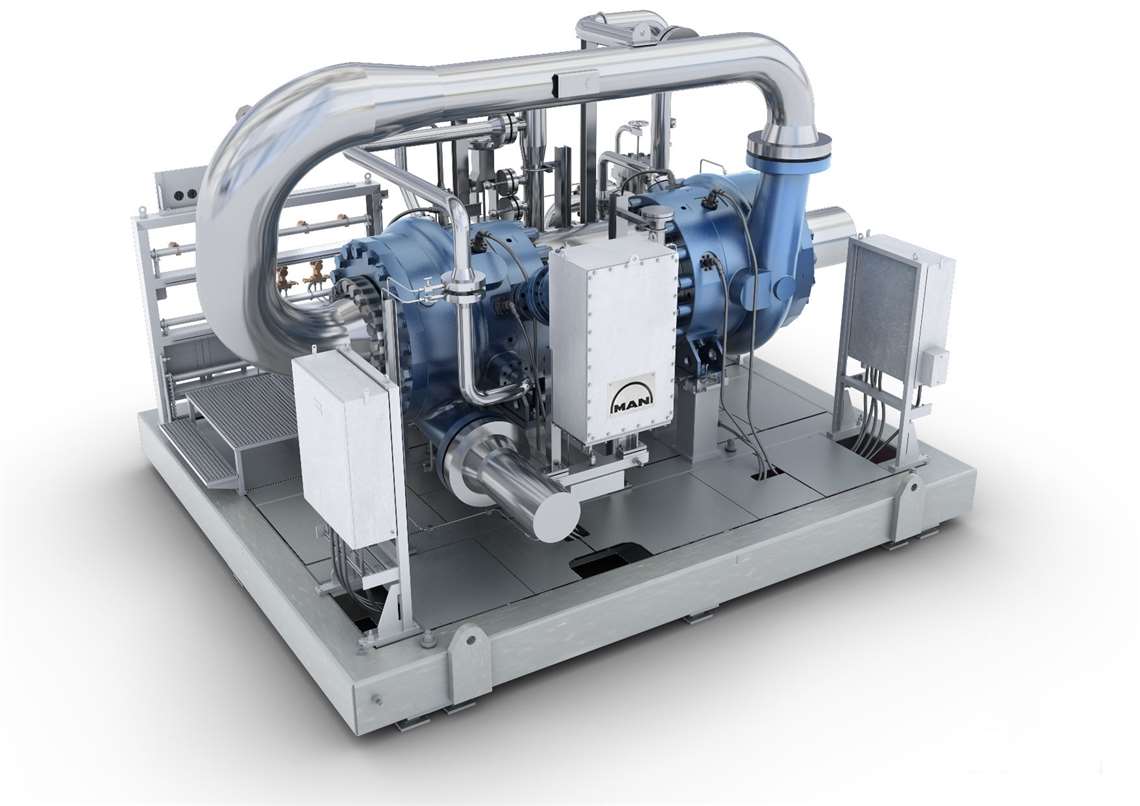

The order includes two MOPICO (MOtor PIpeline COmpressor) RM40 with a MAN M33 motor each and a corresponding active magnetic bearing system system (AMB) supplied by MAN-owned MECOS. In addition to the compressor systems, the scope includes the delivery, planned for summer 2019, as well as their commissioning. The compressor trains are designed, manufactured and tested at MAN Energy Solutions in Zurich, Switzerland.

The compressor systems will be installed in the Estonian towns Paldiski and Puiatu, which are around 200 km apart. In order to enable large volumes of gas to be transported across longer distances, the compressors have to increase the pressure in the pipeline on one hand, but also keep the required pressure level stable on the other, the company said. The MOPICO for Paldiski will compress the natural gas to 943 psi (65 bar) and the MOPICO for Puitatu will then compress it to 798 psi (55 bar).

“Our proven MOPICO systems are hermetically sealed and use the magnetic bearing technology developed by MECOS. As a result, they require little space and are emission- & oil-free,” said Christian Brotel, head of Sales Oil & Gas Midstream. “The cost effectiveness, high efficiency, operational flexibility and low-maintenance nature of our machines are further benefits that we can bring to the customers.”

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM