FFT offers new cassette filter for turbomachinery

November 28, 2022

As the final filter stage, the new spiderMaxx cassette filter is responsible for efficient filtration of the finest particles

Freudenberg Filtration Technologies (FFT) said its new spiderMaxx cassette filters for gas turbines and compressors helps avoid costly machine downtime and losses in efficiency.

The premium filtration performance is designed to ensure clean air in gas turbines for power plants and oil rigs as well as in compressors for a range of industrial applications. spiderMaxx cassette filters offer this performance over a long period of time and reliability even at full load and during load peaks, the company said. They are Efficient Particulate Air (EPA) filter class and feature an increased dust holding capacity and a service life that is around 25% longer than the previous standard cassette filter life, the company said.

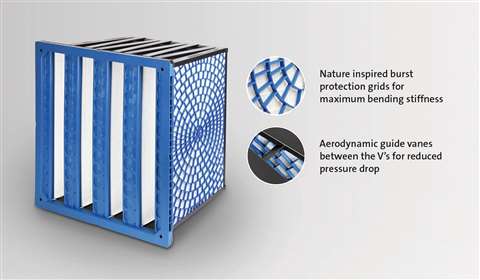

The new spiderMaxx cassette filters offer a series of design refinements. The transfer of phenomena from nature to technological applications is called bionics. Spider webs’ naturally robust design and structure have an extremely high level of resistance. These structures stand up to wind, weather, and insects flying into them at full force.

Inspired by nature, the leakproof casting of this filtration solution features extremely high dimensional stability and resilience. The concentric spider web design of the casting distributes the fluctuating variable mechanical loads that occur during operation across the entire filter frame. This means that the filters can withstand extremely adverse environmental conditions, even those in stormy coastal and offshore regions.

Freudenberg Filtration Technologies (FFT) said its newly developed spiderMaxx cassette filters offer turbomachinery operators maximum performance and operational reliability. Image: FFT

Freudenberg Filtration Technologies (FFT) said its newly developed spiderMaxx cassette filters offer turbomachinery operators maximum performance and operational reliability. Image: FFT

The filter frame, which comprises one-piece front and back plates, offers mechanical stability and torsional rigidity. The frame is optimally sealed to prevent dust from penetrating. The design, which features an integrated channel in the front frame, ensures that the foamed-on gasket fits perfectly, even in critical areas, such as filter corners. The overall leakage risk is close to zero. Water slopes also provide effective water drainage towards the air entry side.

The aerodynamic guide vanes between the v-shaped pleat packages provide a contribution to sustainability. They help ensure a low-turbulence airflow and effectively contain vortex formation on the downstream side. This ensures minimal flow resistance and reduced pressure drop, which results in lower CO2 emissions during operation, the company said.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM