Elliott introduces compressor for hydrogen blend

April 28, 2022

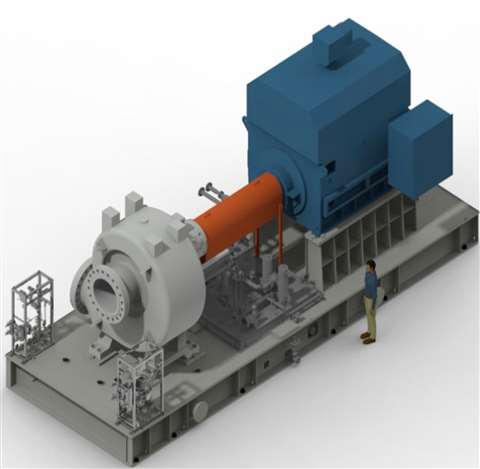

The compressor package incorporates a 140TCH centrifugal compressor with a direct-coupled, high-speed induction motor powered by a variable frequency drive (VFD.) (Image: Elliott Group)

The compressor package incorporates a 140TCH centrifugal compressor with a direct-coupled, high-speed induction motor powered by a variable frequency drive (VFD.) (Image: Elliott Group)

Elliott Group has introduced a compressor designed for current and future low carbon natural gas pipeline transmission networks that can take hydrogen blends up to 50%. The 140TCH pipeline compressor is available with an electric drive and targets new and replacement pipeline stations with strict NOx and CO2 emissions requirements, the company said.

The 140TCH is designed for increasingly complex restrictive emissions regulations. The compressor package incorporates a 140TCH centrifugal compressor with a direct-coupled, high-speed induction motor powered by a variable frequency drive (VFD) connected via standard flexible coupling, Elliott said.

A standard gear-driven solution is also available.

“In the United States, the natural gas situation has changed drastically with the development of local shale gas production and a subsequent focus on curtailing emissions. For these projects, the electric-driven motor solution is optimal. In Europe, the increasing need to import natural gas translates into a need to change the gas transportation and distribution network, and electric-driven compressors are accepted as a low emission alternative to gas turbines,” said Product Introduction Manager Todd Omatick.

Elliott’s 140TCH Pipeline Compressor comes with a direct connect, variable speed (VFD) motor and a standard footprint with custom aerodynamics for optimum efficiency and extended operating time between scheduled overhauls.

The gearless configuration of this compressor package provides a number of advantages, including a smaller footprint, reduced lube oil requirements, and higher net efficiency. The pipeline compressor’s single-lift plug & play design includes auxiliaries (lube oil, buffer gas panel, and integrated, customized controls), and piping and wiring are included on the skid for easy and quick installation with less site work.

It is available seamlessly for 10 to 35 MW applications. In addition, easy access to compressor internals contributes to lower maintenance costs.

Elliott Group designs, manufactures, and services centrifugal and axial compressors, steam turbines, power recovery expanders, and cryogenic pumps and expanders used in the petrochemical, refining, oil & gas, and liquefied gas industries. The company employs 2600 people in 30 locations around the world. Elliott Group is a wholly owned subsidiary of Ebara Corporation, which is based in Tokyo, Japan.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM