Cummins announces “fuel-agnostic” engine platforms

14 February 2022

Cummins Inc. announced that it is expanding its powertrain platforms to leverage a range of lower carbon fuel types for transportation applications. Calling them “the industry’s first unified, fuel-agnostic engines,” the company said the new platforms will use engine blocks and core components that share common architectures and will be optimized for different low-carbon fuel types.

Srikanth Padmanabhan

Srikanth Padmanabhan

Cummins announced that in 2024 it will begin the launch of a range of fuel-agnostic engines, expanding on developments such as its recently introduced X15N natural gas engine. (Photo: Cummins)

Cummins announced that in 2024 it will begin the launch of a range of fuel-agnostic engines, expanding on developments such as its recently introduced X15N natural gas engine. (Photo: Cummins)

“Getting to zero is not a light-switch event,” said Srikanth Padmanabhan, president, Cummins Engine Business. “Carbon emissions that we put into the atmosphere today will have a lasting impact. This means anything we can do to start reducing the carbon footprint today is a win for the planet. We need to take action now.

“Having a variety of lower carbon options is particularly important considering the variation in duty cycles and operating environments across the many markets we serve. There is no single solution or “magic bullet” that will work for all application types or all end users.”

Parts Commonality

Cummins said the new fuel-agnostic engine platforms will incorporate a series of engine versions that are derived from a common base engine, which will yield a high degree of parts commonality. Below the head gasket, each engine will largely have similar components. Above the head gasket, the engines will incorporate different components for different fuel types. Each engine version will operate using a different, single fuel.

Jonathon White

Jonathon White

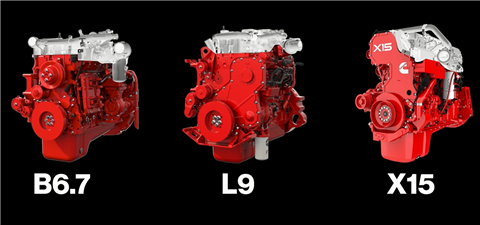

This new design approach will be applied across the company’s B, L and X-Series engine portfolios, which will be available for diesel, natural gas and hydrogen.

“This is a new way of designing and developing lower emission internal combustion powertrains that meet the unique needs of the transportation industry while leveraging the benefits of a common product architecture and footprint where possible,” said Jonathon White, vice president of Engineering, Engine Business. “This unique technology approach will allow end users to more seamlessly pick the right powertrain for their application with the lowest CO2 impact.”

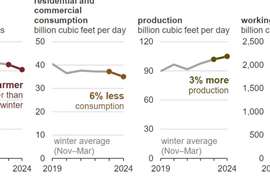

Cummins said that its fuel-agnostic engine platforms will have up to 80% parts commonality with their diesel engine counterparts, with the main differences limited to above the head gasket, as indicated by the highlighted sections. (Photo: Cummins)

Cummins said that its fuel-agnostic engine platforms will have up to 80% parts commonality with their diesel engine counterparts, with the main differences limited to above the head gasket, as indicated by the highlighted sections. (Photo: Cummins)

Cummins said that parts commonality will offer increased benefits for both truck OEMs and end users, including similar engine footprints, diagnoses and service intervals. This means, the company said, that it will be easier for OEMs to integrate a variety of fuel types across the same truck chassis, resulting in minimal costs to train technicians and re-tool service locations, resulting in a lower total cost of ownership for the end user.

“Cummins is innovating at every level of the company to find new ways of working that use fewer of the world’s resources and the Engine Business is at the center of this exciting innovation,” said Padmanabhan. “We know that our planet cannot wait for the perfect solution to happen. Instead, our approach must be a combined effort of using zero emissions power where it’s available and using cleaner power where it is not. The planet cannot afford for us to hit pause in the meantime.”

More information will be included in an upcoming issue of Diesel Progress.

To hear more about Cummins Path to Zero efforts, check out the recent podcast with Cummins CEO Tom Linebarger.