CPC Pumps launches BB5 for CO2 capture

February 17, 2023

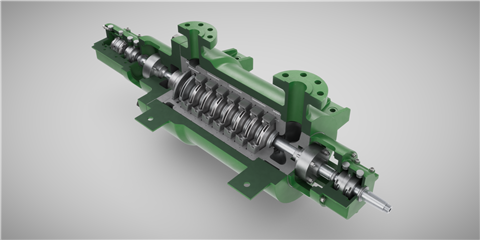

The new BB5 is API 610 compliant. (Photo: Atlas Copco.)

The new BB5 is API 610 compliant. (Photo: Atlas Copco.)

CPC Pumps International has extended its product range with the launch of the BB5, a large pump used in carbon capture and underground storage (CCUS) applications.

Applications for CPC centrifugal pumps are traditionally in the wider refining and petrochemical industries, but the newer BB5 is designed to help customers meet ESG goals.

Fully compliant with API 610 requirements, CPC’s BB5 pump has the option to swap out individual stages in the future, giving the customer the flexibility to adjust their hydraulics. This provides each pump with a wide-ranging, advanced hydraulic coverage that engineers tailor to meet the needs for each application, the company said.

Tushar Patel, general manager of CPC Pumps International, explained that the launch of the BB5 is in keeping with the design ethos that has served the company well for so many decades.

“Each of the BB5 pumps we produce is individually tailored to meet the specific requirements of every customer,” he said.

Atlas Copco bought CPC in August 2021 and integrated it into its Gas and Process division, which makes centrifugal compressors and expanders. CPC Pumps International already has a range of models available, ranging from its OH2 to OH5, VS1/VS6, BB2, and BB3 models. Its BB5 pump expands the range of heavy-duty process pumps for the company.

The BB5 line now extends this product range with what many consider the most robust and extreme of the API 610 offerings. The company said it saw a demand for the pump as the world’s industry is quickly moving to the goal of net zero emissions by 2050.

As an API 610 compliant, its operating specs include:

- Flow rate in excess of 4,400 USGPM (1,000 m3/h)

- Beyond 12,000 ft and 3,660 m respectively (for heads)

- Temperatures up to 840 °F (450 °C)

- Standard design working pressure of 2,250 PSIG (15,000 kpag)

Its standard features include:

- Wide hydraulic coverage

- Application tailored hydraulic selections

- 600/900/1500/2500# flange ratings

- Available in all API 610 table H.1 materials

- Balancing drum or hydraulically opposed impeller arrangement for thrust balancing

- Diffuser & volute designs available

- Integral balance line for minimized chamber pressures

- Robust design shaft for minimal deflection to meet and exceed API 610 requirements

- Inpro/seal bearing housing closures

- Heavy duty baseplate with drip rim or drip pan design

The new BB5 also has a range of optional features available.

- Flange sealing options to suit customer preferences

- High pressure special casing design

- Fan/heat-sink bearing housing cooling arrangement for operation at elevated temperatures, to eliminate the need for cooling water

- Magnetic bearing housing isolators

- All bearing combination arrangements are available where suitable: Ball/Ball, Sleeve/Ball, Tilt pad/Sleeve

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM