Cornerstones of Compression: Quincy Compressor Company

February 06, 2023

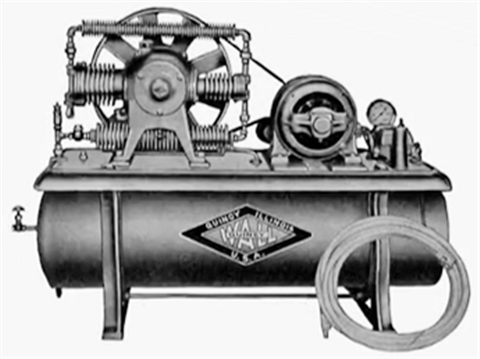

Quincy’s early reciprocating air compressors were two-cylinder arrangements, such as this horizontally opposed two-stage compressor. The bladed flywheel/pulley forced air over cylinder and cooler fins for cooling.

Quincy’s early reciprocating air compressors were two-cylinder arrangements, such as this horizontally opposed two-stage compressor. The bladed flywheel/pulley forced air over cylinder and cooler fins for cooling.

In the years after World War I, George Gille, John Kathe and George Wall of Quincy, Ill., designed a new vacuum pump. In 1920, discovering that the company where they worked had no interest in making it a product, they found financial backing for starting the Wall Pump and Compressor Company in Quincy, Illinois. Their primary products were vacuum pumps for milking cows.

By the end of 1923, the company’s production had grown, and its business expanded further with the development of a small reciprocating air compressor in 1924. Changing its name to the Quincy Compressor Company, the company grew by taking advantage of the increasing demand for compressed air in burgeoning automotive and furnishings markets.

The company’s early reciprocating air compressors were two-cylinder arrangements, either arranged vertically for single-stage compression or horizontally opposed for two-stage compression. They were generally supplied with, or mounted on, an air tank, driven by a small gasoline engine for portable use or a small electric motor for stationary applications. These small splash-lubricated two-cylinder compressors had a number of features that were innovative at the time. The bladed flywheel, which also served as a belt-drive pulley, forced air over fins on the compressor cylinders, intercooler and aftercooler, so that no water cooling was required to deliver relatively cool air to the storage tank. Quincy’s advertising claimed that it was the fastest pumping compressor on the market.

The Quincy QR-25 reciprocating compressor series, first introduced in the 1930s, evolved with many modifications over time. Shown here is an air compressor with a gasoline engine on a portable trailer in use at an airport in the 1950s.

The Quincy QR-25 reciprocating compressor series, first introduced in the 1930s, evolved with many modifications over time. Shown here is an air compressor with a gasoline engine on a portable trailer in use at an airport in the 1950s.

With humble beginnings and adapting to the developing market for air compressors, the company survived the Great Depression and continued to grow. In the late 1930s, Quincy introduced the QR-25 reciprocating compressor series that evolved with many modifications over time to continue in production to this day.

Quincy QR-25 compressors were used by the U.S. Navy in World War II to fill pontoon boats. By c.1952, more than 600,000 Quincy compressors had been produced, finding use in countless applications.

The line continued to expand in range including introduction of four-cylinder vee models in 1968. Diverse applications included use in large mining shovels, NASA rocket transporters and starting air compressors on U.S. Navy and Coast Guard tug boats.

Quincy’s lines of belt-driven reciprocating compressors have evolved into many sizes derived from the original QR-25 series. The two-stage QT series retained the original splash-lubricated design. Maximum pressure capability was increased to 175 psig (12 bar) over time. Two-cylinder 1000 rpm vertical models now range from small 3.0 in. (76 mm) stroke, 5 hp (3.7 kW) machines to a 3.5 in. (89 mm) stroke, 10 hp (7.5 kW) size. Four-cylinder vee models extended the splash lubricated machines to 15 hp (11.2 kW) at 1150 rpm.

Many of Quincy’s smaller air compressors, such as the vertical and vee-type models shown here, have been supplied mounted on air receivers.

Many of Quincy’s smaller air compressors, such as the vertical and vee-type models shown here, have been supplied mounted on air receivers.

At some point in the product evolution, oil pumps were added to provide pressurized lubrication of the compressor bearings.

This configuration became the modern Quincy QR-25 and QP reciprocating air compressor series. A wide range of 100 psig (6.9 bar) single-stage and 200 psig (13.8 bar) two-stage models were developed, ranging from about 2 to 25 hp (1.5 to 18.6 kW).

Quincy also developed higher pressure models up to 250 to 500 psig (17.2 to 34.5 bar), depending on the size. The largest of these models was rated at 30 hp (22.4 kW).

Quincy has sold its reciprocating compressors as bare units for special applications, but many have been tank mounted or skid mounted as complete systems with an electric motor or small engine, controls and other accessories. Many have been sold with noise attenuation enclosures of various styles.

Over the years, Quincy developed many accessories for air compressor systems, such as air dryers, filters, air coolers, and receivers/tanks.

In 1966, the Quincy Compressor Company was purchased by Colt Industries. Quincy had obtained a license for rotary screw air compressors from SRM some years earlier, and the acquisition by Colt helped set the stage for the development of a Quincy rotary screw compressor line.

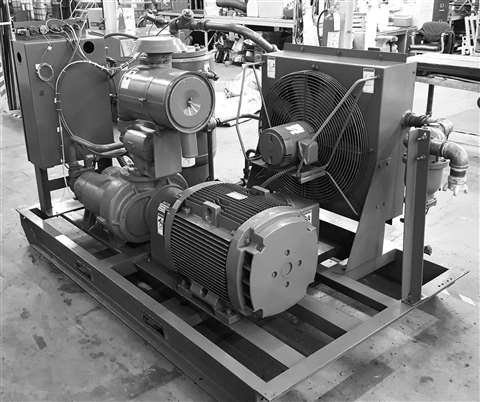

A c.2005 Quincy rotary screw compressor in the process of being packaged with an electric motor drive for a low-pressure gas engine starting air application.

A c.2005 Quincy rotary screw compressor in the process of being packaged with an electric motor drive for a low-pressure gas engine starting air application.

From the late 1960s onward, Quincy developed an extensive line of oil-flooded rotary screw air compressors. Over time, machines with 100 and 125 psig (6.9 and 8.6 bar) pressure capabilities were introduced in rotor diameters from 5.0 to 12.64 in. (127 to 321 mm) and power ratings from 50 to 400 hp (37 to 298 kW).

Although some bare compressors were sold for special applications, Quincy generally has offered its rotary screw machines as complete compressed air systems with electric motor, controls, filters, dryers, receivers, etc. housed in cabinets for noise reduction. Some have been supplied with variable frequency drives. Some of the smallest units included speed increasing gears or speed increasing belt-drives.

In 1980, Quincy built a new plant in Bay Minette, Alabama for compressor machining and manufacturing operations. That plant was expanded in 1996, with production continuing there today.

In the early 1990s, with increasing demand for natural gas compressors for mature gas wells, coal-bed methane, landfill gas and similar applications, Quincy adapted both its reciprocating and rotary screw compressors for compression of natural gas.

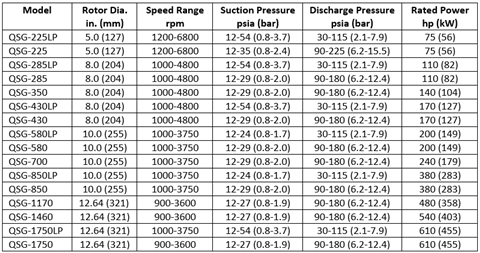

Specifications for the Quincy rotary screw gas compressor models, c.2016.

Specifications for the Quincy rotary screw gas compressor models, c.2016.

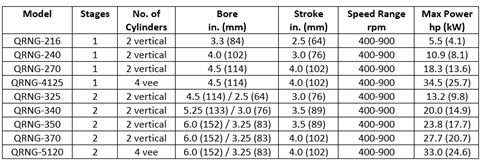

Specifications for the Quincy reciprocating gas compressor models, c.2016.

Specifications for the Quincy reciprocating gas compressor models, c.2016.

These compressors also found use in vapor recovery and fuel gas boosting applications. The screw compressors were equipped with patented lift valves for capacity and load control. Both the reciprocating and screw compressors were sold as “bare shaft” units that were packaged by various companies serving niche gas compression markets.

In 1998, Coltech was purchased by the Goodrich Corporation. But, in 2002, faced with growing exposure from asbestos claims in some of the engineered products companies that it had acquired from Coltech, Goodrich spun the companies off as Enpro Industries, Inc., a new corporation.

The Quincy Compressor Company was among the companies included in Enpro. In 2004, Quincy expanded with a new operation in Kunshan China for the assembly and testing of rotary screw compressors for the global market. In 2009, Quincy Compressor was purchased by Atlas Copco, and in 2020, Quincy’s headquarters were officially moved to Shanghai, China. The company continues to manufacture both the reciprocating and rotary screw compressor lines.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM