John Crane launches dry gas seal diagnostics

January 25, 2022

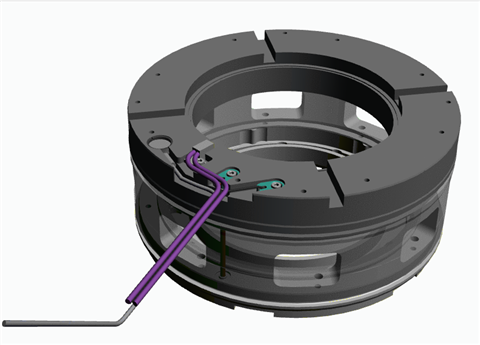

The John Crane Sense Turbo uses a unique set of sensors embedded directly into a compressor’s dry gas seal to deliver continuous, real-time insight to identify potential issues.

The John Crane Sense Turbo uses a unique set of sensors embedded directly into a compressor’s dry gas seal to deliver continuous, real-time insight to identify potential issues.

John Crane recently launched dry gas seal digital diagnostics solution to monitor conditions at the heart of the compressor.

The product, John Crane Sense Turbo, uses a unique set of sensors embedded directly into a compressor’s dry gas seal to deliver continuous, real-time insight to identify potential issues and ensure corrective actions are taken to extend the useful life of the seal.

The technology is designed to improve reliability, reduce the risk of failures and unplanned downtime and increase the mean time between repairs while increasing efficiency and profits, the company said.

John Crane Sense Turbo uses a four-step data flow process:

- Sensors collect data on conditions that impact seal health,

- Data from different sensors is combined, processed at the edge, uploaded to the existing process control system (PCS) and distributed control system (DCS), and sent to cloud servers for additional real-time processing and archiving, using industrial-grade cybersecurity,

- Real-time pre-set alerts and alarms are sent to applicable devices and

- Access to secured and actionable information is available on any device, using enterprise-grade cybersecurity in the cloud with multifactor-protected data portals

“Leveraging machine learning, John Crane Sense Turbo allows customers to assess the health of dry gas seals installed in turbomachinery and understand how to optimize the reliability and performance of their rotating equipment,” said John Crane Product Line Director, Digital, Brian Boykin. “By understanding the remaining useful life of a mechanical seal, our customers can add months, if not years, to the time before repair of their equipment, while significantly reducing maintenance costs at the same time.”

John Crane Sense Turbo is part of the John Crane Sense platform and suite of solutions designed to transform industrial equipment to build a better understanding of asset health through the digitization of critical components.

Sense is an open platform for a suite of apps that provide actionable information. Throughout 2022, John Crane will launch two additional digital monitoring solutions focused on wet seals and monitoring other plant equipment:

John Crane Sense Pumps: A digital health monitoring system that leverages years of experience in mechanical seal expertise, combined with machine learning technology to provide insight into the health and performance of the pump asset.

John Crane Sense Monitor: A wireless monitoring solution that enables visibility into asset health and performance across the entirety of the plant or site, including in the most remote locations.

The John Crane Sense open platform is designed to allow third parties, component OEMs and end users to digitize their physical devices with application development support from John Crane.

“The launch of John Crane Sense Turbo is our first of many offerings to help our customers improve the health of their operations through digitization. John Crane Sense helps customers by being their digital eyes and ears in the plant, so they can protect what matters,” said John Crane CEO and Division President Jean Vernet.

MAGAZINE

NEWSLETTER

CONNECT WITH THE TEAM